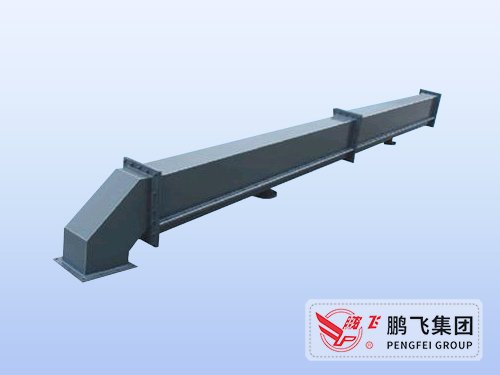

Overview: The air conveying chute can be used for easily fluidized powder materials such as cement and fly ash. The chute is powered by a high-pressure centrifugal fan (9-19:9-26 type) to keep the material in the closed conveying chute flowing slowly at the inclined end of the fluidized state. The main body of the equipment has no transmission part and adopts a new type of coated wheel breathable layer. The sealing operation and management are convenient. The equipment is lightweight, low power consumption, high conveying force, and easy to change the co...

Tel: +86-513-88755311 88755027

An air conveying chute is a device that uses airflow to transport granular materials along a pipeline. There are three types: suction type, pressure type, and hybrid type. Its working principle is to use the kinetic energy of the airflow to suspend the granular material and transport it along the pipeline with the airflow ① Suction type. After the exhaust fan is started, the entire system maintains a certain degree of vacuum. Under the action of pressure difference, the air flow causes the material to enter the suction nozzle and be sent along the conveying pipe to the separator at the discharge point. The material is separated from the air flow and discharged from the bottom of the separator. The airflow is purified by the dust collector and then discharged into the atmosphere through the muffler. The advantage is that the feeding is simple and the material can be simultaneously extracted from several sources. But the conveying distance is short and the productivity is low. High sealing requirements ② Pressure delivery type. The blower presses air into the conveying pipe, and the material is supplied from the feeder. The mixture of air and material is conveyed along the conveying pipe to the discharge point. The material is discharged after passing through the separator, and the air is purified by the dust collector before being discharged into the atmosphere. The characteristics are opposite to the suction type, which can simultaneously transport materials to several places, with a longer conveying distance and higher productivity, but the structure is complex ③ Mixed type. A combination of the two forms mentioned above.

| Canvas chute | Porous plate inclined groove | ||||

|---|---|---|---|---|---|

| Slant width (mm) | Conveying capacity (i=6%) | Slant width (mm) | Conveying capacity at different slopes (m³/h) | ||

| 4% | 5% | 6% | |||

| B250 | ~30 | B250 | 40 | 50 | -- |

| B315 | ~60 | B400 | 80 | 100 | 120 |

| B400 | ~120 | B500 | 120 | 150 | -- |

| B500 | ~200 | B600 | 160 | 200 | -- |