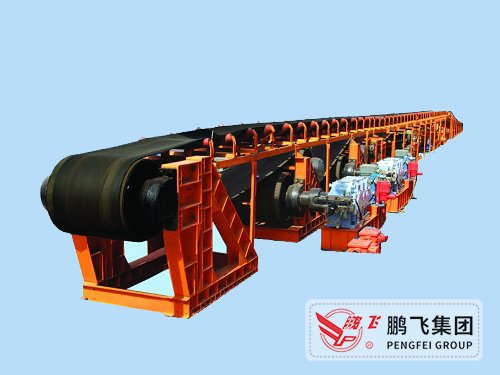

Overview: Belt conveyor is the abbreviation for belt conveyor, which can be fixed or mobile, with a simple structure and high efficiency. A continuous conveying machinery that uses flexible conveyor belts as material carrying and traction components. An endless conveyor belt surrounds the drive drum and the reversing drum. The upper and lower branches between the two rollers are supported by several rollers. The material is placed on the upper branch, and the friction between the driving drum and the belt is used to pull the conveyor belt and the materia...

Tel: +86-513-88755311 88755027

Belt conveyors have the characteristics of simple structure, easy maintenance, low energy consumption, and low operating costs. In addition, they also have the following features: 1. There are many types of materials that can be transported, including various loose materials, as well as lightweight products such as cardboard boxes and packaging bags. They can also be used for transporting goods at the checkout of large supermarkets, with a wide range of applications 2. There are various structural forms of belt conveyors, including groove belt conveyors, flat belt conveyors, climbing belt conveyors, inclined belt conveyors, turning belt conveyors, etc. The conveyor belt can also be equipped with accessories such as push plates, side baffles, skirts, etc., which can meet various process requirements 3. The belt conveyor adopts specialized food grade conveyor belts, which can meet the requirements of industries such as food, pharmaceuticals, and daily chemical industry 4. The conveying is smooth, and there is no relative movement between the material and the conveyor belt, which can avoid damage to the conveyed material 5. Compared with other conveyors, it has lower noise and is suitable for working environments that require quietness.

1. Fixed conveyors should be installed on a fixed foundation according to the prescribed installation method. Before the official operation of the mobile conveyor, the wheels should be wedged with triangular wooden wedges or braked with brakes. To prevent movement during work, when multiple conveyors are operating in parallel, there should be a one meter passage between machines and between machines and walls 2. Before using the conveyor, it is necessary to check whether each operating part, tape buckle, and bearing device are normal, and whether the protective equipment is complete. The tension of the tape must be adjusted to a proper degree before starting 3. The belt conveyor should be started with no load. Only after normal operation can the material be fed in. It is prohibited to feed before driving 4. When several conveyors are running in series, they should be started sequentially from the discharge end. Only after all are operating normally can the material be fed in 5. When the tape deviates during operation, it should be stopped for adjustment and not forced to be used to avoid wear on the edges and increased load 6. The working environment and the temperature of the delivered materials shall not exceed 50 ℃ and shall not be lower than -10 ℃ 7. Pedestrians or passengers are prohibited on the conveyor belt 8. Before parking, the feeding must be stopped first, and the parking can only be done after all the materials stored on the belt have been unloaded 9. The conveyor motor must have good insulation. Do not pull or drag the cables of the mobile conveyor randomly. The electric motor should be reliably grounded 10. It is strictly prohibited to pull the belt by hand when it slips, in order to avoid accidents.

1. Check all fasteners and confirm that they are not loose 2. Clean the belt and confirm that it is intact. If the belt is found to be damaged, it should be replaced in a timely manner 3. Check the lubricating oil inside the motor gearbox and ensure it is functioning properly 4. Check the tension of the belt and adjust it to the appropriate level.

| Tape width (mm) | Conveying length (m)/power (kw) | Conveyor speed (m/s) | Conveying capacity (t/h) | ||

|---|---|---|---|---|---|

| 400 | ≤ 12/1.5 | 12-20/2.2-4 | 20-25/4-7.5 | 1.3-1.6 | 40-80 |

| 500 | ≤ 12/3 | 12-20/4-5.5 | 20-30/5.5-7.5 | 1.3-1.6 | 60-150 |

| 650 | ≤ 12/4 | 12-20/5.5 | 20-30/7.5-11 | 1.3-1.6 | 130-320 |

| 800 | ≤ 6/4 | 6-15/5.5 | 15-30/7.5-15 | 1.3-1.6 | 280-540 |

| 1000 | ≤ 10/5.5 | 10-20/7.5-11 | 20-40/11-22 | 1.3-2.0 | 430-850 |

| 1200 | ≤ 10/7.5 | 10-20/11 | 20-40/15-30 | 1.3-2.0 | 655-1280 |